Revolutionize Your Industrial Heating with TKE-HTT™

(Thermal Kinetic Energizer Heat Transfer Technology)

The TKE-HTT™ is a patented, high-performance combustion system designed to replace traditional industrial gas burners. Created by inventor Carl Mörsner, this breakthrough in energy-efficient heating helps industrial operations advance their green steel and decarbonization goals.

Why Should You Choose TKE-HTT?

We understand the pressure to meet emissions reduction targets, improve fuel efficiency, and lower your operations costs.

TKE-HTT™ directly supports these objectives by reducing your processing times, cutting pollution and noise levels, lowering your maintenance costs, and helping you save on your energy bills.

How TKE-HTT Works: A Clean Combustion Breakthrough

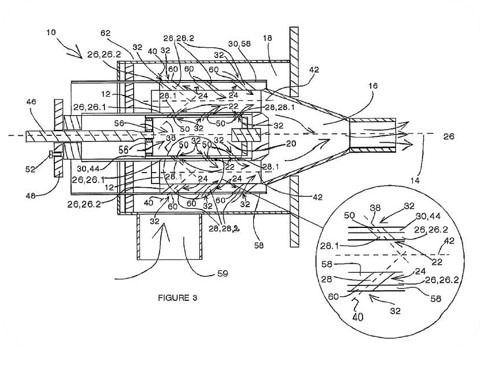

Unlike conventional combustion systems that depend on visible flames, radiation, or convection, TKE-HTT™ transfers heat through kinetic energy. Combustion gases exit the system at 721 feet per second, creating fast-moving molecules that evenly distribute energy.

These molecules induce mechanical vibration when they collide with denser materials, dramatically improving thermal conductivity and enabling uniform heating. This creates a clean and effective heat-transfer process.

Smarter Combustion vs. Conventional Burners

TKE-HTT™ burns cleaner than conventional burners by containing 95% of the combustion reaction inside the unit, significantly reducing visible flames and harmful byproducts. When fired into a closed environment like a furnace, it also eliminates the usual “jet engine” sound by reducing friction, which allows for uniform heating, helps to improve safety, and keeps shop floors cooler.

- Ladle Preheaters

- Ladle Dryers

- Tundish Preheaters

- Stationary Forging & Reheating Furnaces

- Torpedo Cars

Putting TKE-HTT To THe Test

With goals to increase ladle preheater reliability, eliminate hot and cold spots within the ladle, and reduce natural gas consumption, this customer turned to TKE.

Click to read the full case study>>

With a fleet of 20 ladles, 2 ladle dryers, and 11 ladle preheaters, a large Midwest steel producer experienced issues with its combustion systems that led to downtime, product quality issues, and increased utility usage.

Click to read the full case study>>

WANT AN UNFAIR COMPETITIVE ADVANTAGE?

If you need your facility to save on natural gas, time, and money, it turns out you're in good company. We just can't tell you who these people are because of their unfair competitive advantage with TKE-HTT.

SAVE ENERGY

SAVE TIME

SAVE MONEY

JOIN THE INDUSTRIAL HEATING REVOLUTION

Whether you're retrofitting outdated burners or launching a new facility, TKE-HTT is the smart choice for modern manufacturers seeking efficiency, safety, and sustainability.